Why work with Coating Technologies LLC. for your plating needs?

- High Quality Plating Services

- Strong commitment to customer service

- Capable of managing complex requirements

- Extensive employee and management plating experience

- Dedication and emphasis on quality systems

- NADCAP accreditation

Our Approved Processes

Electroless Nickel PTFE

Approved Process Numbers

- AMS2454

- GPS 3117-1

- M7019883

- HP4-90

- EMS52545

- P.S. 10-27

Electroless Nickel

Approved Process Numbers

- AMS-C-26074

- ASTM-B733

- AMS 2404

- GPS 3108-1

- M695215

- HP4-10

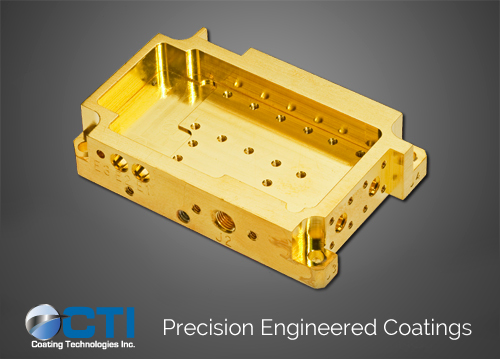

Gold Plating

Approved Process Numbers

- MIL-DTL-45204

- ASTM-B488

NP3 / Electroless Nickel PTFE

Approved Process Numbers

- AMS2454

- GPS 3117-1

- M7019883

- HP4-90

- EMS52545

- P.S. 10-27

Black Oxide

Steel & Stainless Steel

Approved Process Numbers

- AMS 2485

- MIL-DTL-13924

- M690330

- HP4-50

- BPS4084

Zinc & Manganese Phosphate

Approved Process Numbers

- MIL-STD-171

- MIL-DTL-16232

- HP4-7

Passivation

Approved Process Numbers

- AMS2700

- ASTM-A-967

- ASTM-A-380

- GPS3000-1

About CTL

Established in 1986 Coating Technologies LLC. delivers superior quality and strict attention to detail on every plated component through training, adherence to procedures, honesty, cooperation with the customer and an ongoing commitment to excellence.

Providing Electroless Nickel, Electroless Nickel / PTFE (NP3), Black Oxide, Phosphating and Passivation. Coating Technologies is an experienced and trusted supplier to industrial, commercial, military, aerospace and defense contractors.

Let our experienced staff help provide a quality solution for your application.

Additional Services

- Masking

- Abrasive blasting, sand or glass

- Pre-plate Stress Relief and Hydrogen Embrittlement Baking

- Expediting